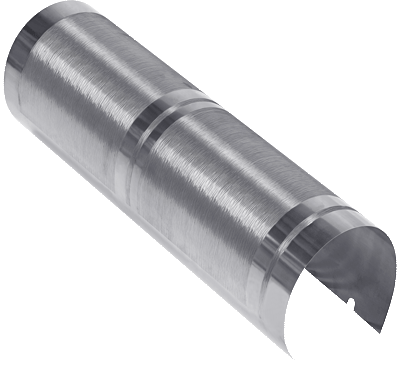

Flexible dies

Focus on maximum quality

Flexible dies

Work with absolute precision

- Suitable for all types of materials: paper, PP, PE, PVT, PET, Tyvek, thin films on PET liner material, etc.

- Profile heights range from 0.30 to 1.5 mm.

- Cutting angles vary from 30° to 110° depending on the material.

Advantages of our flexible dies

Get the best results

Types of flexible dies

Discover everything we can offer

Laser Hardening

They are suitable for long runs and abrasive materials that make die cutting difficult. Hardness of 65-68 HRC by laser hardening.

Crome Coating

Nanotec is an ultra-thin microcoating with a hardness of over 80 HRC. It reduces friction and is phenomenally wear-resistant, so its cutting edge stays razor sharp throughout its exceptional service life.

Non Stick Coating

Is the perfect solution for a wide range of tasks due to its excellent non-stick properties in standard applications. It has a special coating that prevents glue and ink deposits.

The greatest versatility at your service

This is how our flexible dies are

The flexible dies can be used on both cylinders and flat magnetic bases. Each die is manufactured according to the client’s needs, giving the option of combining different types of cut and height (perforation and creasing).

- Cutting angle: 30º – 110º – adjusted to the properties of the face material.

- Cutting Height: 0.30-1.5mm – adjusted to the release liner thickness.

- Minimum corner radius 0.00 mm, perfectly sharp corner.

- Maximum cut quality through improved cutting geometry.