Focus on maximum quality

Ultrasonic welding

Take your productivity to the maximum

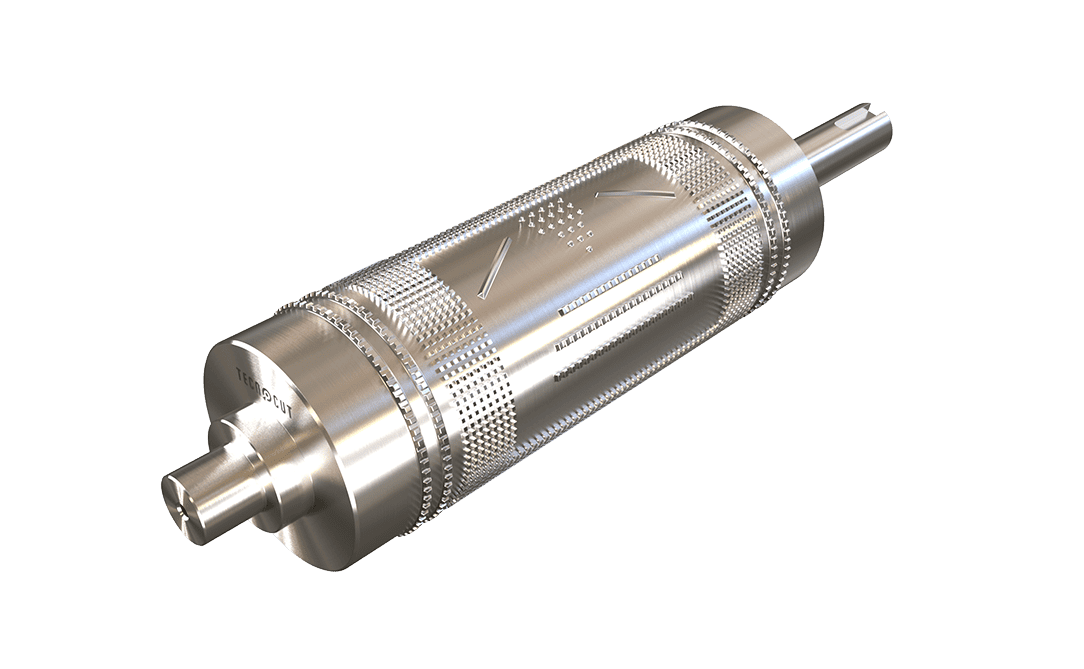

The ultrasonic welding cylinders for the production of surgical masks can be adapted to any type of rotary machine.

- It helps to achieve very good results results in terms of strength, tightness, and visual appearance.

- The resulting friction heat melts the material directly at the joining points of the individual material layers.

- Because of low energy consumption, the material undergoes very little thermal stress.

Advantages of working with ultasonic welding

Get the best results

Higher performance

Allows high-volume production in the textiles, medical, hygiene, filter, and general technical industries

100% adaptable

Ultrasonic welding systems (or ultrasonic modules) can also be easily integrated into production lines.

High quality

If the combination of materials, the anvil profile, and the ultrasonic system are appropriately designed.

Save costs

Ultrasonic welding enables to work on high speed, while saving energy and avoiding production downtime.

Applications of the ultasonic welding

Discover everything you can do

When welding nonwovens in combination with longitudinal seals, high-strength connections are established at the joint areas. Rotary ultrasonic systems are particularly suitable for joining applications in marginal areas.

Benefits / special features:

- Additional web material transport

- Fast processing

- Tight and strong connection

When welding cross seals, instantaneous peak power must be precisely controlled and introduced into the joint areas in a minimum of time. For such applications, correct selection of the anvil geometry and the ultrasonic system is of particular importance.

Benefits / special features:

- Consistent and uniformly strong connection

- High product throughput per minute

- Soft hand feel

Targeted joining of several layers of nonwovens by means of ultrasonics and an anvil drum with structure. Bonding of the material web is merely performed in “spots”, which prevents any adverse effects e.g. on filter properties or stretching behavior of elastic composites.

Benefits / special features:

- Energy-saving

- No adhesives required

- Fast processing

- Textile hand feel is maintained

- Low energy consumption

- Color designs possible without additional print

- High process speeds

- Process control

- Fiber-free perforation

- Fiber-free welding of cutting edges

- High production speeds

- Material splices in end product-quality