Tecnocut

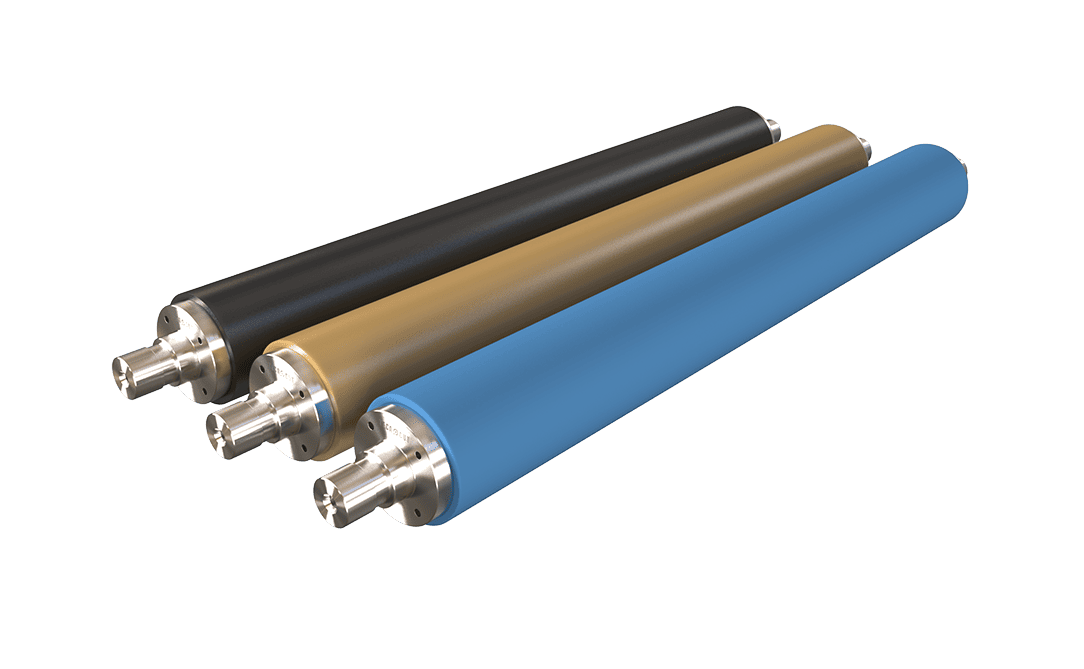

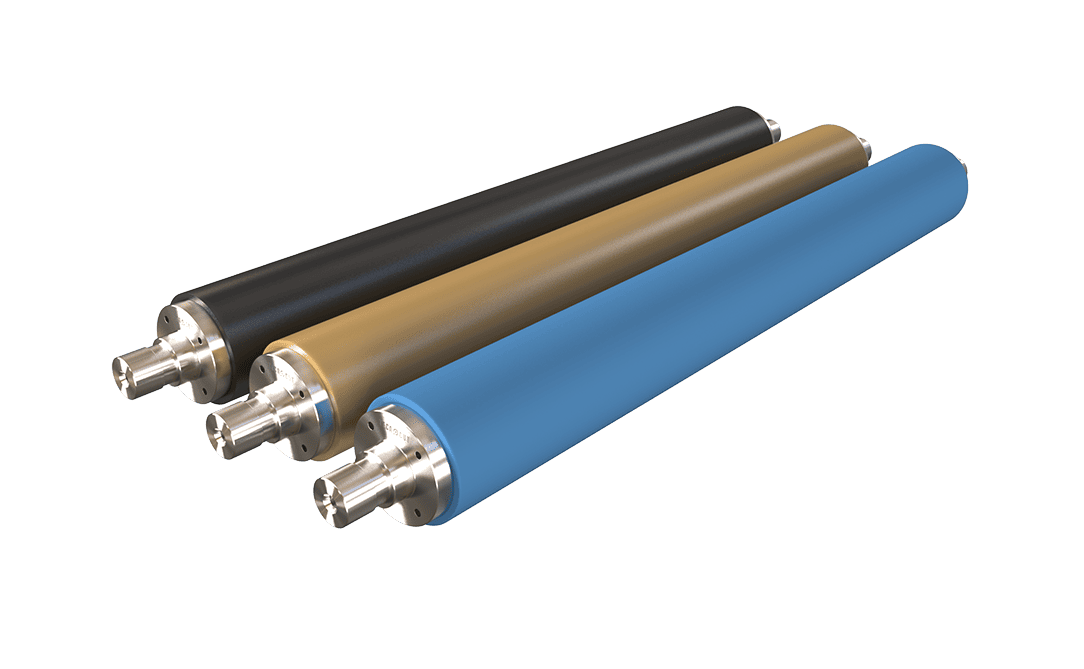

Rubber cylinders

Manufactured in high quality materials acording to the needs of each project

Focus on maximum quality

Rubber cylinders

Bet on the best materials

Rubber cylinders are manufactured in all types of materials having in mind the purpose of each client and project.

- Commonly, rubber cylinders applications are related to the material application, the improvement of the movement and material support & transport..

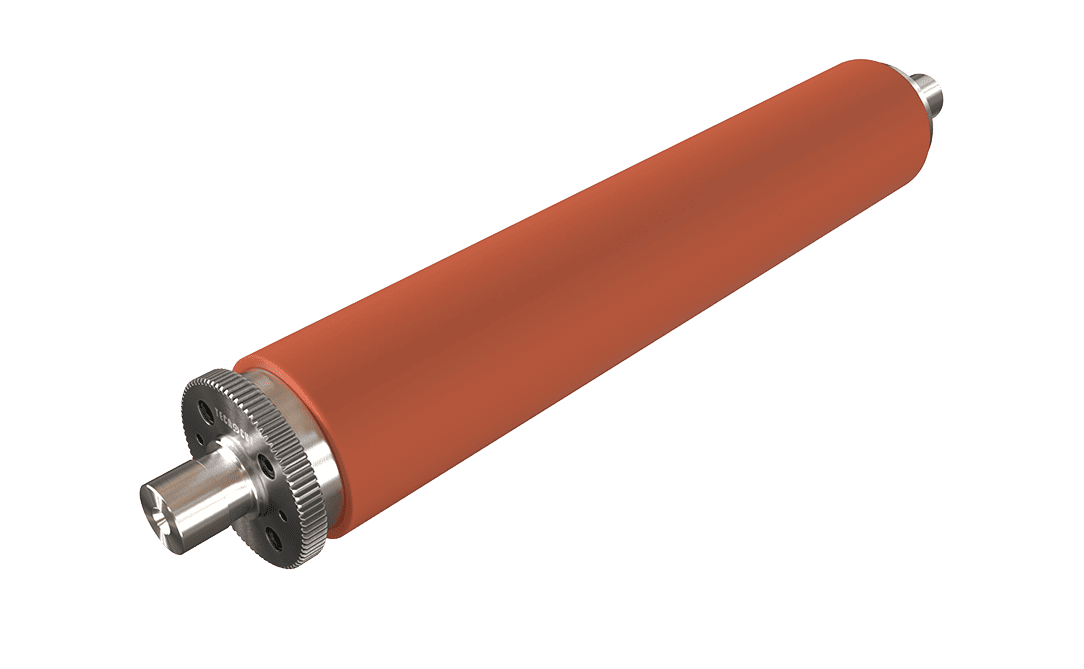

- We could change the damaged rubber or manufacture the complete new rubber cylinder..

- Rubber cylinders offer all of the advantages of rubber itself: it can be repeatedly compressed and relaxed, it can absorb shocks and resist against damage and scratching..

Advantages of using our rubber cylinders

Designer for maximum durability

High quality

Designed with high quality materials, durability and even performance according to the needs of each client.

Higher performance

Rubber cylinders have high coefficient of friction, which provides great traction in moving parts and components.

Save costs

Rubber is also fairly inexpensive to extract and manipulate, it also can be removed and recycled again and again.

100% adaptable

Having in mind its use, rubber cylinders are manufactured with different measurements or hardnesses.

Rubber cylinders materials

Discover its features

The elastomeric materials from which manufacturers can choose from is fairly varied.

- Materials that are frequently used to fabricate rubber cylinders: EPDM, silicone, nitrile, neoprene, polyurethane and natural rubber.

- Metal core rollers are usually made with steel, stainless steel, aluminum or another metal that fits application requirements

- Each material has its own strengths and weaknesses, but all of them have some level of resistance to water, wear, certain chemicals and heat extremes.