Cylinder Checking Tool

TECNOCUT

Focus on maintenance

Cylinder Checking Tool

Control your cylinder’s tolerance easily

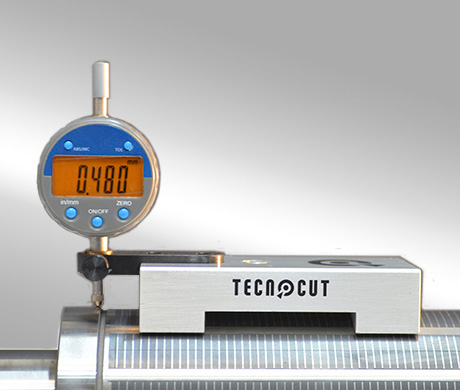

The cylinder checking tool allows us to measure the light gap (airgap) of the magnetic cylinders.

- Is used to perform maintenance and detect those that need repair or replacement.

- Is made up of a robust clamping system incorporated into the dial indicator and it can measure the cylinders on both sides.

- Allows detecting that the cylinder is die cutting correctly, without cutting too deep or too shallow.

Invest in cylinder checking and save costs

Discover this tool’s advantages

This is how our cylinder checking tool works

Understand the results easily

The results of the cylinder checking tool can be classified according to three bands:

- Correct: indicates that the magnetic is in correct operation with acceptable tolerances of +/- 3 micros. Ideal measurement: 0.480 mm

- Acceptable: indicates that the magnetic has imperfections or is on the verge of going out of accepted tolerances.

- Poor: suggests that the magnetic cylinder should be immediately removed from inventory due to its tolerance issues.